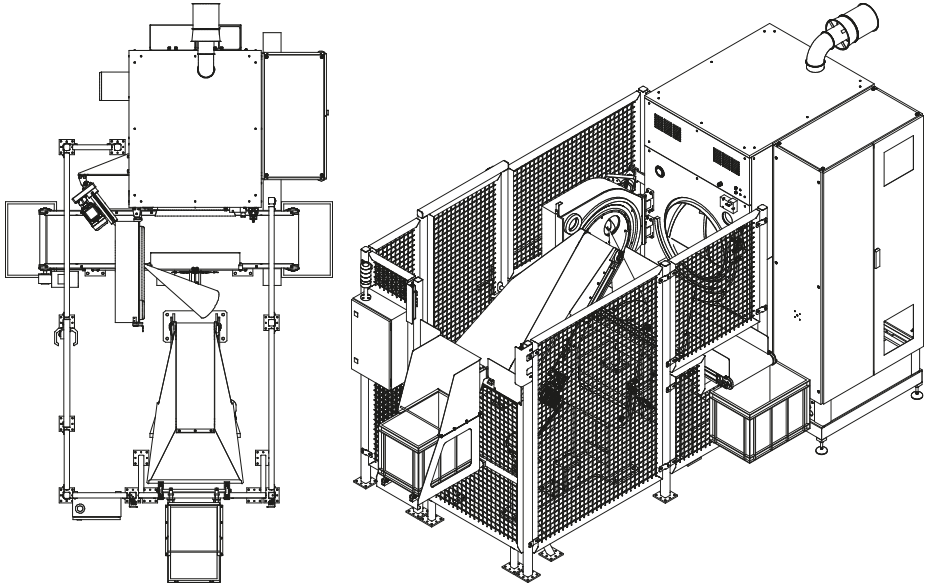

Washing, drying and coating systems

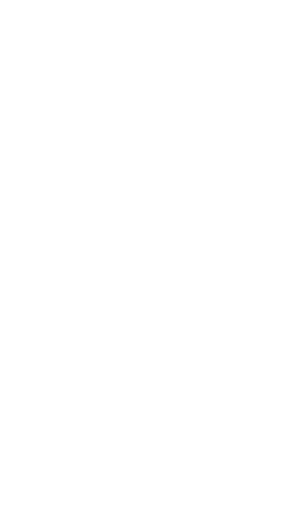

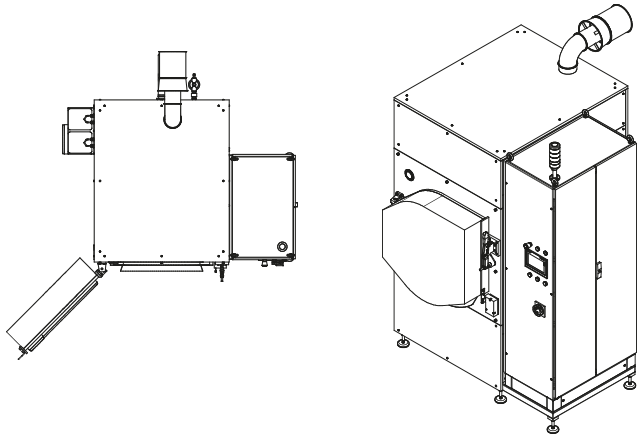

AWW 40 // AWW 40 CUBE

The simple and robust construction offers an economical solution for washing and drying components. And this with optimal process documentation. The S7-1500 controls, in combination with a modern HMI touch panel and barcode reader, allow for user-friendly operation of the system.

We also manufacture machines with individual batch volumes and moulded part requirements according to your remit.

Constantly clean

The standard features

Controls

> Siemens S7-1500 with TP 700 Comfort touch panel

Water heating

> Using a flow heater

> 20 °C – 60 °C, steplessly adjustable

Drying

> High pressure ventilator and heat register

> 30 °C – 90 °C, steplessly adjustable

Housing

> Sound-insulating enclosure

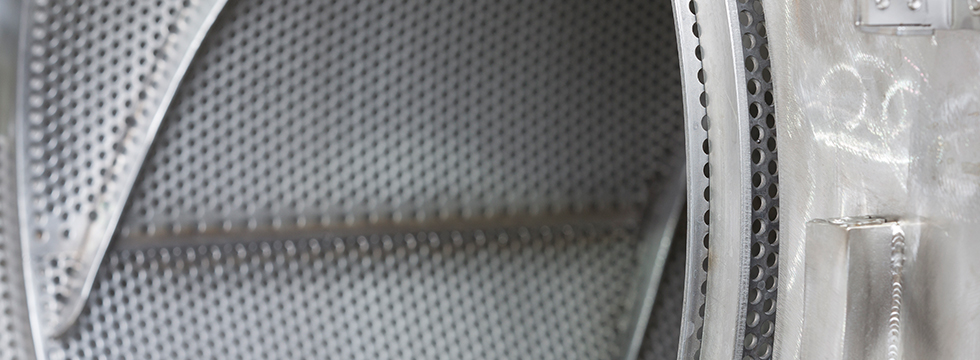

Processing drum

> Perforated removable basket

> Possible options

Drum speed

> 7 – 60 rpm

Data management (LAN, USB)

> External protection of the formulas

> Complete batch documentation

Technical details for the AWW 40 // AWW 40 CUBE

- Housing sound-insulating enclosure

- Controls Siemens S7-1500 with TP 700 Comfort touch panel incl. barcode reader

- Control cabinet positioning integrated into the side of the housing

- Process documentation data management via LAN and/or USB

- Batch volumes up to 40 litres

- Basket volumes 146 litres

- Basket geometry cylindrical with roller rails

- Basket speed 7 – 60 rpm

- High pressure rinsing high pressure pendulum nozzle up to 200 bar

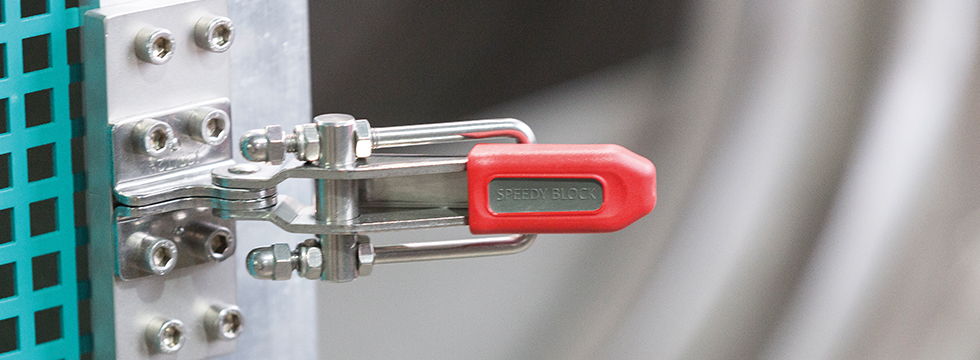

- Feeding door manual

- Water temperature 20 °C – 60 °C, steplessly adjustable

- Drying temperature 30 °C – 90 °C, steplessly adjustable

- Dosing pumps 2 dosing pumps incl. reservoirs (washing agent, silicone oil, antistatic agent, etc.)

- Seals low-wear sprung PTFE seal / special door seal

- Compressed air supply not required

- Article memory 4,000 items

- Construction solid base frame with levelling foot, suitable for forklifts

- Weight approx. 660 kg

- Dimensions 1,500 B x 2,300 D x 2,200 H

- Electrical connection 400/230/24 V/50 Hz/N/PE/3Ph/50A

- Water connection 1/2“

- Waste water connection 2“

- Exhaust DN 120

- Heat output 16 KW

Simple and secure data handling with integrated USB and LAN interface. Recipes can be called up simply and safely with the barcode reader. Integration of the machines in internal company structures with remote access and online machine access is possible. OPC-UA is available as a universal communication interface on all our machines

The basket can be swapped and a variety of basket perforations are therefore available. Tailored exactly to your requirements according to the moulded part sizes. Loading occurs manually via the manually operated exterior door. The basket is automatically emptied by means of the integrated roller rails.