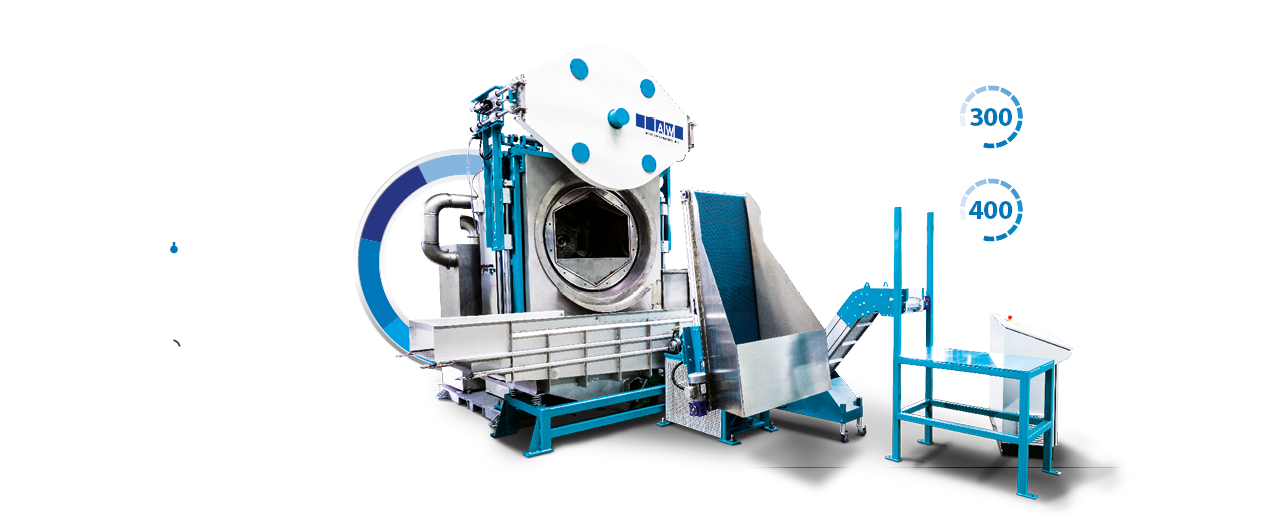

Cryogenic drum deflashing

AWT 300 // AWT 300+

The AWT 300 offers an ideal solution for the cryogenic drum deflashing of rubber and PUR elastomer moulded parts. Thanks to drum geometry which is optimised for your product and the innovative LN2 direct spraying, the best deflashing results can be achieved here in the shortest times with minimal nitrogen consumption. High-quality processed materials and extremely robust construction offer the user the maximum safety.

The AWT 300 is suitable for large volumes and is used for the pre-deflashing of rubber moulded parts or the finishing of PUR elastomer components thanks to the steel ball agglomerate. The S7-1500 controls, in combination with a modern HMI button paneland barcode reader, allow for user-friendly operation of the system.

The standard features

Processing drum

> Selectable version (cylindrical or square)

Controls

> Siemens S7-1500 with KP 900 Comfort button panel

Dust extraction exhaust system

> Integrated, isolated cyclone dust extraction

> Additional extraction

Moulded part cooling

> Temperatures as low as -150 °C

> LN2 direct spraying

Insulation

> 120 mm thick insulation cell

Agglomerate management

> Automatic agglomerate return

> Optimal separation

Data management (LAN, USB)

> External protection of the formulas

> Complete batch documentation

Emptying sieve

> External sieve with vibration motor

> Changeable sieve inserts

> Multi-level

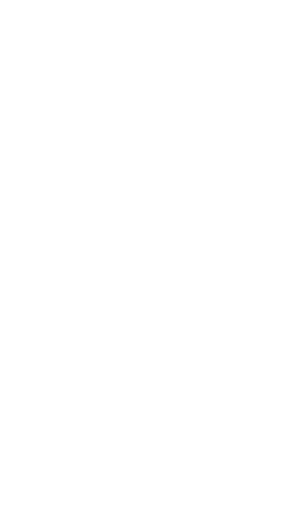

Technical details for the AWT 300 // AWT 300+

- Insulation welded stainless steel cell with 120 mm PU foam insulation

- Controls Siemens S7-1500 with KP 900 Comfort button panel incl. barcode reader

- Control cabinet positioning as a console

- Process documentation data management via LAN and/or USB

- Batch volumes up to 300 litres (AWT 300+: up to 400 litres)

- Drum volumes 540 litres (AWT 300+: up to 950 litres)

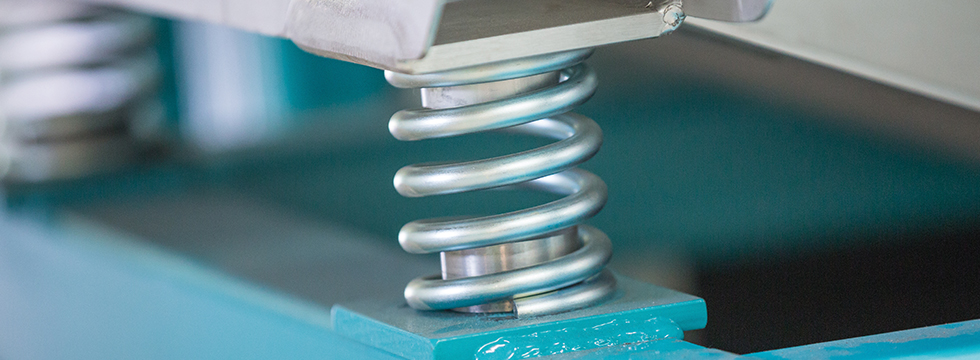

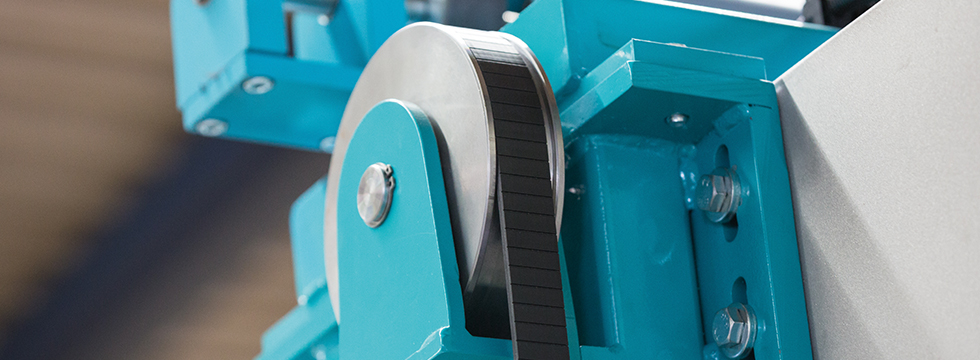

- Drum geometry cylindrical or square with roller rails

- Drum speed 5 – 60 rpm

- Loading door operated manually or automatically by an electric motor

- Loading swivelling conveyor belt

- Dust extraction integrated, isolated cyclone dust extraction with service door

- Seals low-wear metal alloy / special door seal

- Compressed air supply not required

- Heat output 9,700 Watts

- Article memory 4,000 items

- Temperature regulation PID regulator down to -150 °C

- Construction solid base plate incl. forklift slots

- Weight approx. 3,500 kg

- Dimensions 2,900 B x 6,300 D x 3,300 H (AWT 300+: Dimensions on request)

- Electrical connection 400/230/24 V/50 Hz/N/PE/3Ph/50A

- Nitrogen input 1/2“, 4.5 bar

- Exhaust DN 175

Simple and secure data handling with integrated USB and LAN interface. Recipes can be called up simply and safely with the barcode reader. Integration of the machines in internal company structures with remote access and online machine access is possible. OPC-UA is available as a universal communication interface on all our machines.

The overhung processing drum can be implemented as a cylindrical or square drum according to the customer‘s requirements. The solid mounting allows for maintenance-free operation of the drive system. The innovative door seal achieves the longest possible service life and optimal sealing of the processing area.

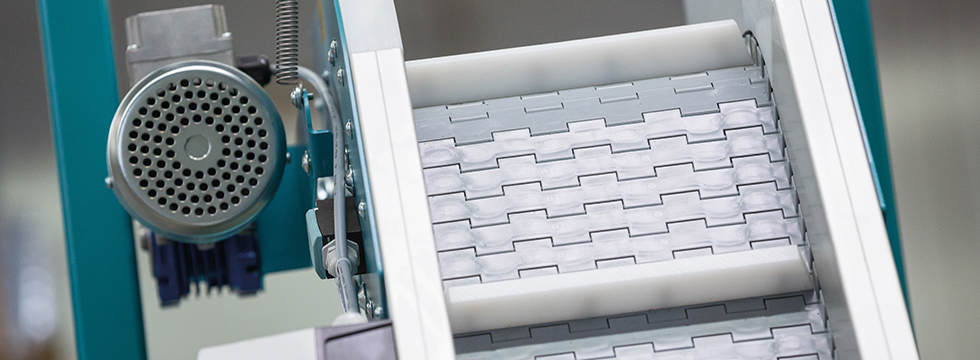

The external, multi-level vibration sieve works with frequency-controlled vibration motor technology. The moulded parts and residual flashing are separat-ed efficiently thanks to the changeable sieve inserts. The agglomerate (steel balls) is separated automatically. Additional extraction carries dust-like residual flashing particles into the integrated cyclone.

The loading door is opened and closed at high speed by an electric motor. The moulded parts to be deburred are automatically fed into the machine via a conveyor belt system. Emptying after the end of the batch and refilling then occurs automatically. This can also be combined with upstream and downstream conveyor technology through to batch tracking by means of barcodes or RFID technology. In combination with the safety technology supplied, we naturally comply with all of the safety regulations here.